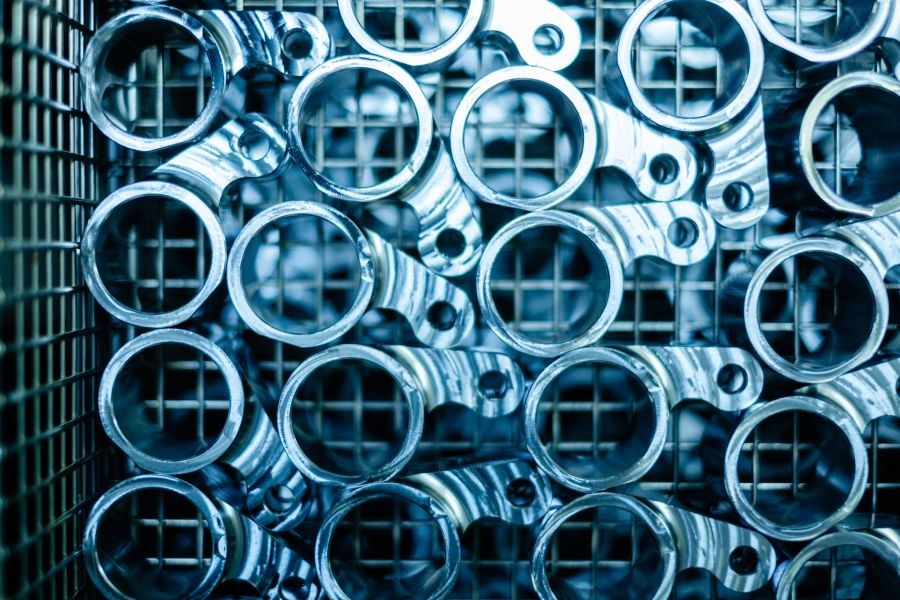

Company Holidays Over the Christmas Period

From December 24, 2025 to January 2, 2026 inclusive, Metalux Metallveredelung GmbH will be on company holidays. During this period, production, shipping, and administration will be unstaffed. Starting January 5, 2026, we will be back to serve you as usual.

We will process incoming inquiries as quickly as possible upon our return.