Our laboratory makes

the difference

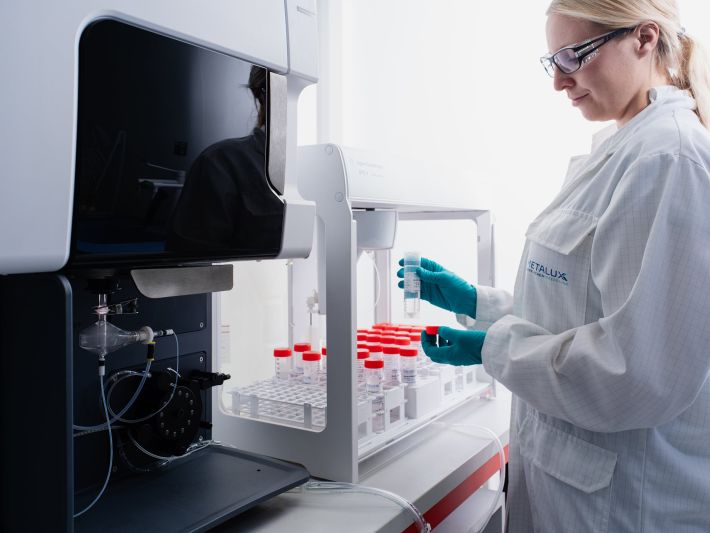

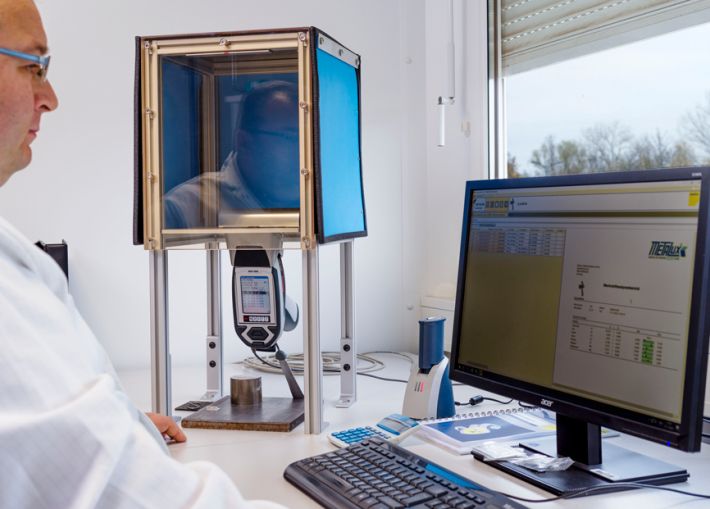

Seamless quality control for maximum reliability

Our in-house laboratory ensures the quality of your components from the very first processing step. Reliable, documented and with state-of-the-art technology. Daily bath analyses, precise process and result checks and careful documentation guarantee consistently high coating quality.