Hard anodising

Highest wear resistance for aluminium surfaces

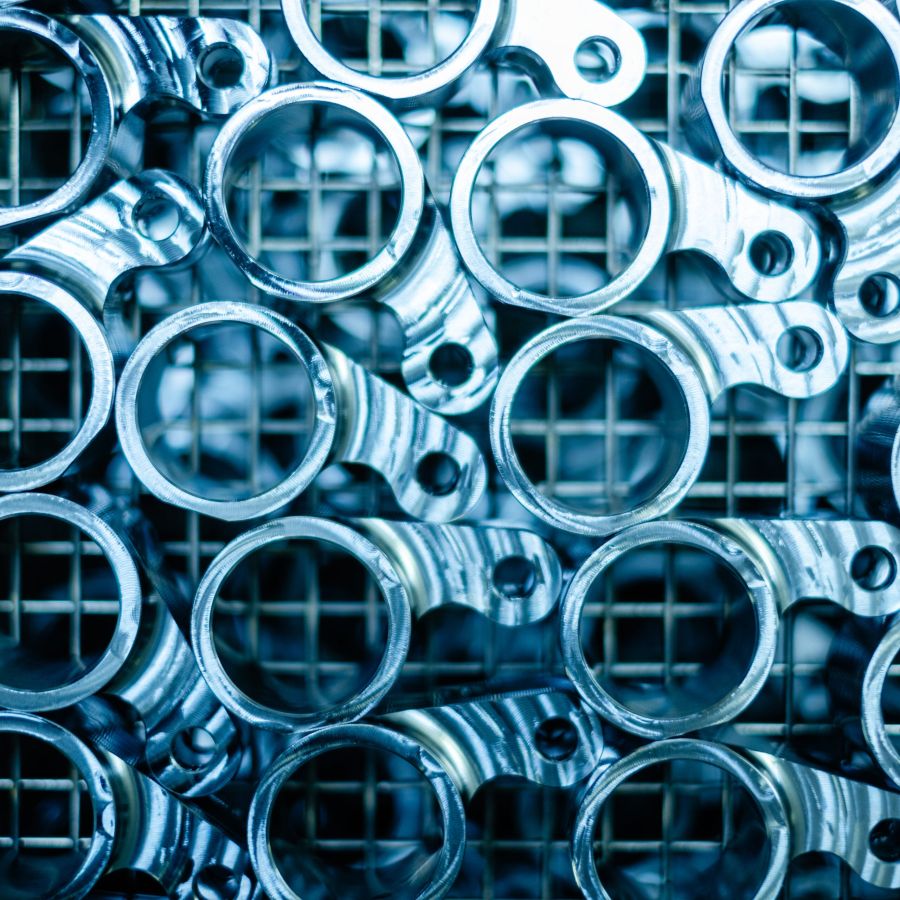

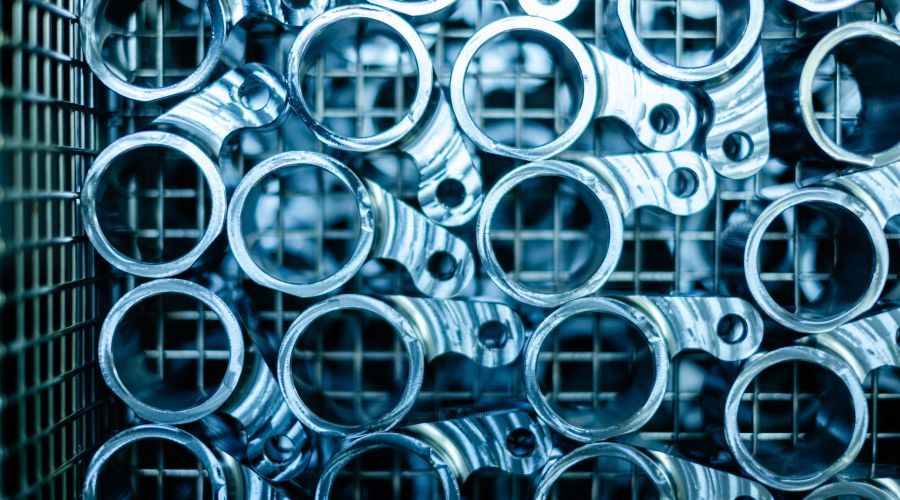

Hard anodising, also known as hard anodising or hard coating, is an electrolytic process for surface refinement of aluminium. Anodic oxidation creates an extremely hard, ceramic-like protective layer that protects the material against wear, corrosion and thermal stress. Particularly in demanding industrial applications, hard anodising is the first choice for durable and resilient aluminium components.

Hard-anodised aluminium surfaces offer decisive advantages for high-performance applications:

Ideal for components subject to high mechanical stress

Langlebiger Schutz vor Umwelteinflüssen

Hardness of up to 500 HV possible

Ideal for thermally stressed components

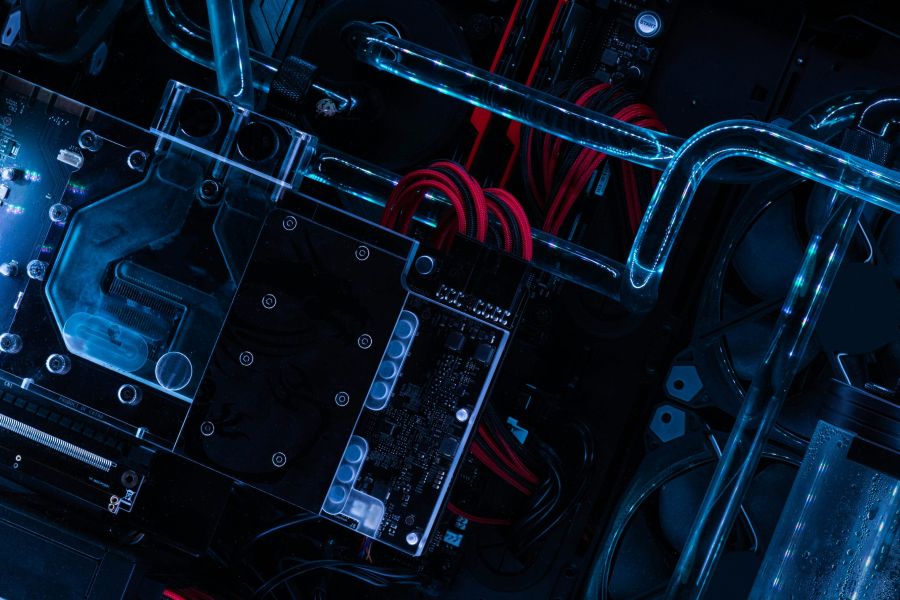

Potential breakdown voltage of over 3000 V possible

Hard anodised coatings are characterised by a variety of functional properties:

Perfect protection for mechanical applications

Ideal for high-temperature areas

High breakdown voltage for electrical applications

Heat shielding due to oxide layer

The layer is inseparably bonded to the base material

Hard anodising is an electrolytic process that is carried out in several precise steps:

The aluminium is degreased and cleaned to ensure optimum adhesion.

The extremely hard aluminium oxide layer is formed in the cold acid electrolyte through anodic oxidation.

A final treatment provides additional corrosion protection and optimised coating properties.

Hard-anodised aluminium components are ideal for applications with the highest mechanical, thermal or electrical loads:

Mechanically highly stressed components with maximum wear resistance

Lightweight but extremely robust components

Optimal corrosion and abrasion resistance for chassis and engine parts

High-voltage insulation and thermal shielding

Mechanisch hochbelastete Bauteile mit maximaler Verschleißfestigkeit

Leichte, aber extrem widerstandsfähige Komponenten

Optimale Korrosions- und Abriebfestigkeit für Fahrwerks- und Motorteile

Hochspannungsisolierung und thermische Abschirmung

Hard anodised surfaces have a natural colour ranging from grey to black, depending on the aluminium alloy. Additional black colouring is possible through adsorptive colouring. Due to the dense and hard layer structure, other colours can only be achieved to a limited extent and require individual coordination.

Depending on requirements, different layer thicknesses can be realised.

Usual layer thicknesses | 30 – 80 μm, in special cases up to 150 μm |

Layer growth: | Approx. 50 % into the material, 50 % out of the material |

Due to the growth characteristics, material shortages can occur at sharp edges. Constructions with larger radii of curvature improve the layer quality and prevent chipping.

| Procedure / Processing | Length in mm | Width in mm | Depth in mm |

|---|---|---|---|

|

Chromic acid and hard and sulphuric acidanodise |

4600

|

420

|

1300

|

|

Sulphuric acid and hard anodising, various colours |

2600

|

300

|

1000

|

Hard anodising creates a thicker, harder and more wear-resistant oxide layer than conventional anodising. The layer is also more thermally and electrically insulating.

In principle, almost all aluminium alloys can be hard anodised. However, the copper content should be below 2% to achieve optimum results.

No, hard-anodised coatings are electrically insulating. Depending on the alloy and layer thickness, the breakdown voltage is over 3000 V.

Only black colours are possible due to the dense and hard structure. Other colours must be individually matched.

Hard-anodised coatings are extremely heat-resistant and can withstand temperatures of up to 2,200 K for short periods of time.