Passivation

Protection & corrosion resistance for stainless steel & metals

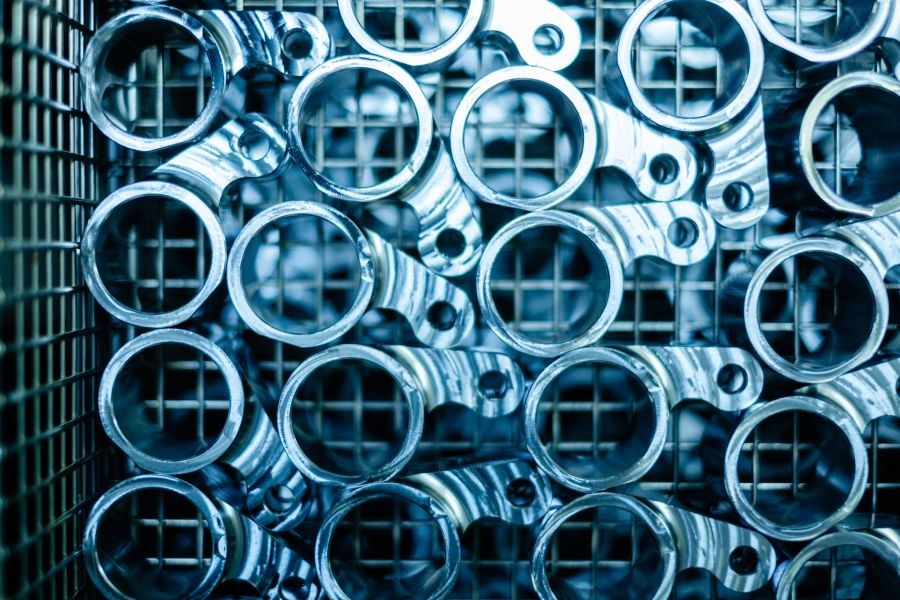

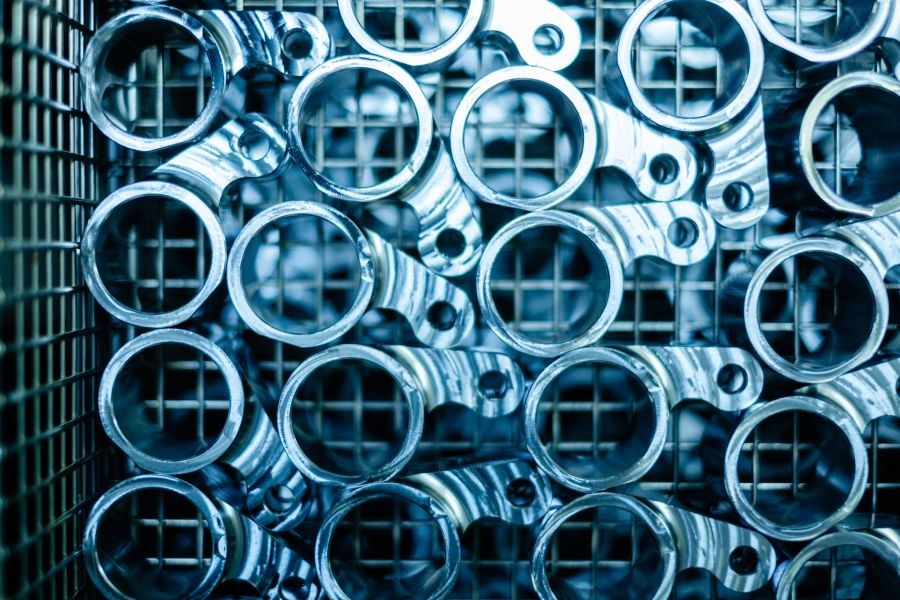

Passivation is a chemical process for forming a protective layer on metallic surfaces. This passive layer prevents or significantly slows down the oxygen corrosion of the base material.

During the passivation process, foreign particles such as oxide layers or alloy components are removed, while the natural passive layer is strengthened. The result is a dense, self-healing protective layer that improves corrosion protection and increases the longevity of the material.

Passivated components are resistant to corrosion, environmental influences and mechanical stress.

Passivation offers many advantages for metal processing and corrosion protection:

Fit surfaces with tolerances ≥ 2 μm are retained

Passivation layer renews itself when damaged

Interior areas & drill holes are also treated

Denser and more resistant layer than untreated surfaces

Passivation is not only suitable for new components, but also for the restoration and maintenance of already corroded surfaces.

Restoration of the protective layer

Additional protection without prior staining or blasting

Subsequent protection for stressed components

This makes it particularly suitable for complex components that require even protection.

As passivation is a chemical process, it also reaches hard-to-reach areas such as:

Passivation is a proven process, especially for stainless steels with a high chromium, nickel and molybdenum content.

Passivated surfaces offer a variety of technical advantages:

Metalux offers passivation in various sizes and weights. Our systems are designed to meet a wide range of requirements in order to realise individual customer wishes.

| Procedure / Processing | Length in mm | Width in mm | Depth in mm |

|---|---|---|---|

|

80-T-35-1200 Supplement 2 |

760

|

220

|

700

|

|

AMS 2700 Typ 2 |

760

|

220

|

700

|

|

AMS 2700 Typ 8 |

970

|

270

|

700

|

|

AMS 2700 Typ 7 |

760

|

220

|

700

|

|

80 – T – 35 – 1200 Supplement 1 |

2600

|

440

|

1000

|

|

AMS 2700 Typ 1 |

2000

|

310

|

1000

|

|

DIN EN 2516 C 2 |

2600

|

440

|

1000

|

Passivation is mainly used for stainless steels with a high chromium, nickel and molybdenum content. These include:

Haftvermittler für Lackierungen & Klebeverbindungen

Geringer Kontaktwiderstand für leitfähige Verbindungen

The selection of the right process depends on the alloy & the intended use of the component.

Non-rusting steels form a thin passive layer by themselves, which can be reinforced and compacted by artificial passivation.

Yes, passivation is also suitable for restoration & maintenance and helps to stop corrosion damage.

On contact with oxygen, the protective layer can renew itself after damage, thereby maintaining the corrosion protection.

No, as it is a purely chemical process without metal removal, the surface remains intact.

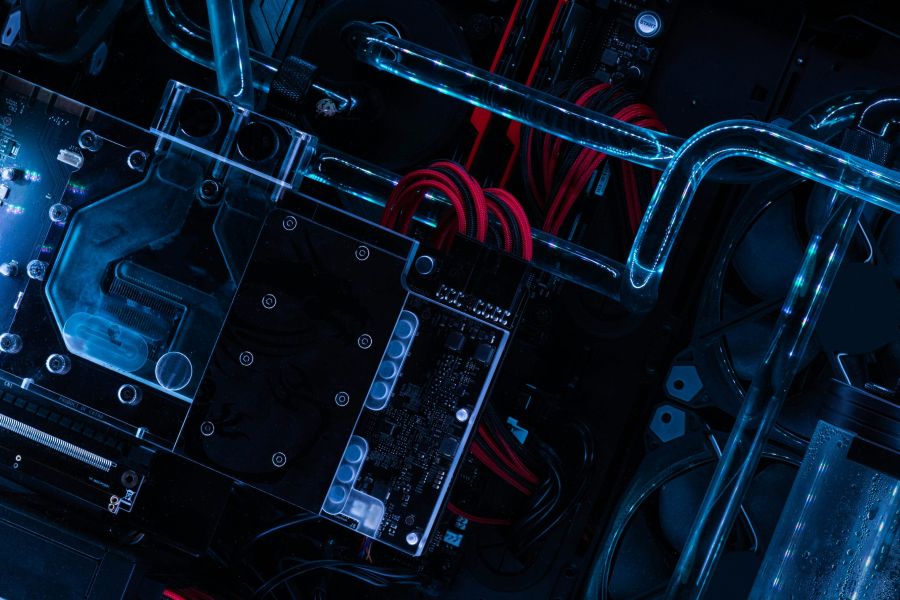

Passivation is used in the aerospace, medical technology, food industry and mechanical engineering sectors.