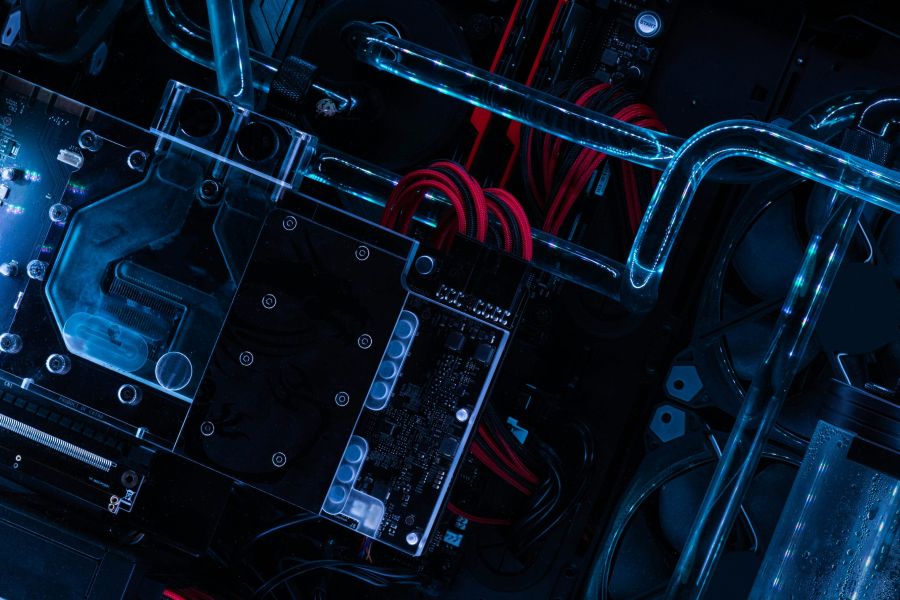

Masking & lasering

Precise surface treatment & labelling

Masking is a tried-and-tested process for the targeted protection of certain surfaces, drill holes or fitting dimensions during surface processing. This allows different areas of a component to be specifically treated or omitted.

Lasers enable precise labelling, cleaning or structuring of surfaces – contact-free, dimensionally accurate and without chemical residues. Whether for labelling, marking serial numbers or removing coatings – lasers offer maximum flexibility for industrial applications.

The latest laser technology can be used to mark, clean or structure surfaces – quickly, efficiently and without removing material.

Lasers can also be used to remove oxide layers or unwanted coatings in a targeted manner – ideal for reconditioning or cleaning components.

No mechanical stress on the workpiece

Ideal for serial numbers & codes

Reduction of the processing effort

No chemicals or residues

Masking protects certain areas of a component from subsequent surface treatment. This is particularly important if different material properties or functionalities are to be retained on a workpiece.

Through professional masking, we ensure that your components are finished exactly to the desired specifications.

Paint stripping and cleaning with laser technology enables the targeted removal of coatings such as oxide layers or paints – precisely in the μm range.

Thanks to this technology, components can be efficiently reconditioned and reused without causing mechanical stress.

Whether the smallest details or large-scale markings – the laser process offers maximum precision in every dimension.

Laser marking is a fast and robust method of permanently labelling components. It is used in many industries to make components traceable or to apply customised markings.

Laser technology is suitable for a wide range of materials:

Stainless steel, aluminium, titanium

ABS, polycarbonate, acrylic

ABS, polycarbonate, acrylic

Thanks to the versatility of lasers, almost all materials can be permanently, precisely and economically labelled or structured.

Laser technology enables the permanent engraving of barcodes, QR codes and serial numbers for seamless traceability in industry.

This form of labelling is an integral part of modern industrial and production processes.

Masking is used to protect certain areas of a component from surface treatment.

Yes, laser markings are extremely durable and resistant to abrasion, chemicals & UV radiation.

Lasers are non-contact, environmentally friendly & highly precise – ideal for permanent labelling.