Anodising

High-quality surface finishing for aluminium

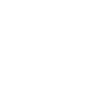

Anodising (electrolytic oxidation of aluminium) is a surface finishing process that makes aluminium more resistant to external influences. Electrolytic treatment transforms the aluminium surface into a protective oxide layer. This layer increases corrosion resistance, improves wear resistance and provides a high-quality, decorative surface finish.

Anodising is a process for the surface treatment of aluminium. By means of anodic oxidation, a protective layer can be created on the metal, which prevents the natural, uncontrolled oxidation of the metal through the reaction with oxygen from the ambient air. The oxide layer grows 1/3 out of the metal and 2/3 into the metal. Anodising produces layer thicknesses of 5 – 25 micrometres.

Ideal for components subject to mechanical stress

Protection against environmental influences and chemicals

No flaking or peeling of the coating

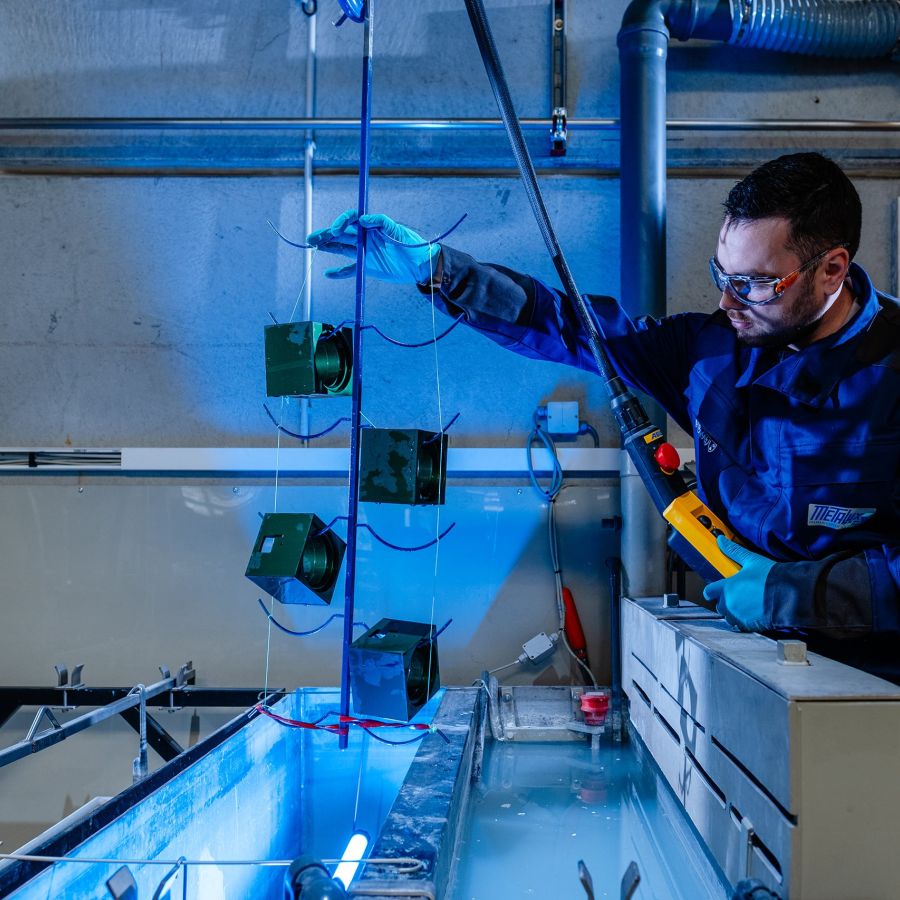

Technically anodised aluminium is used wherever durability, protection and functionality are required. Typical areas of application are:

Protection against wear and chemical influences

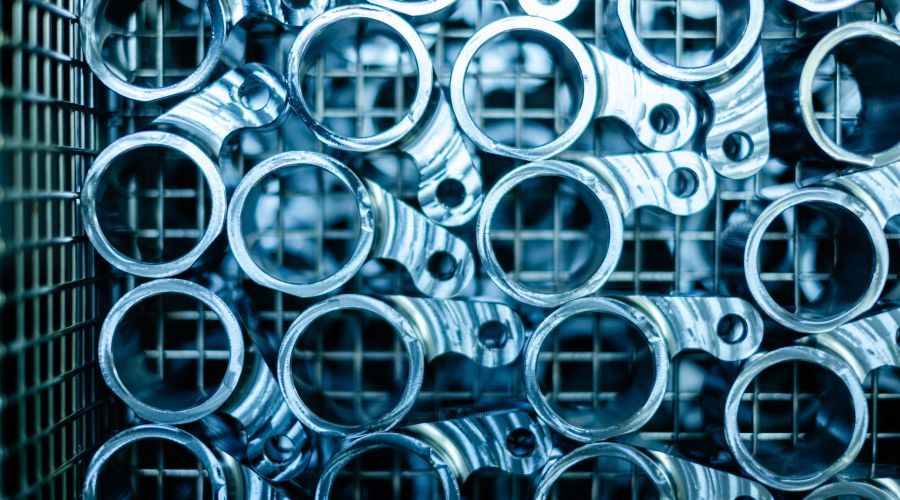

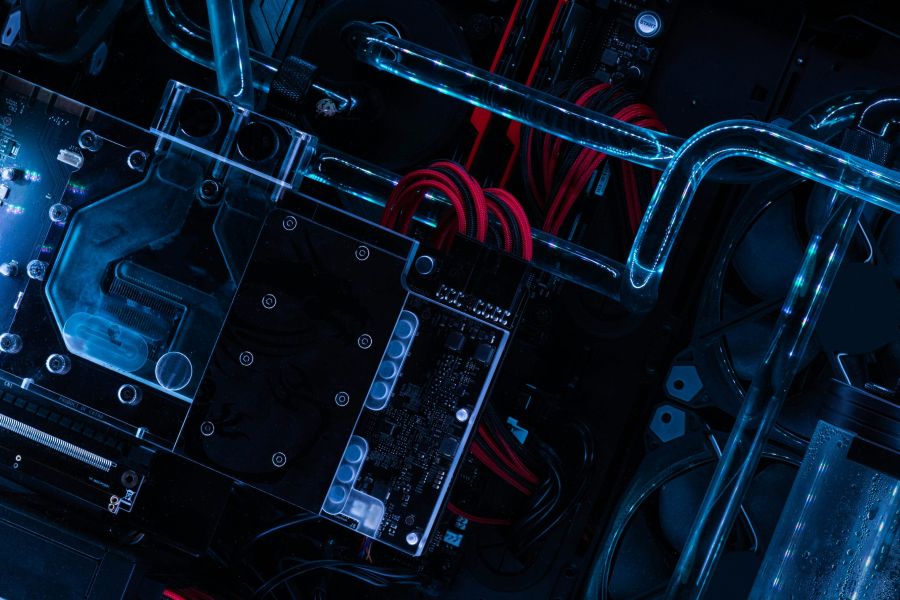

Insulating layers for printed circuit boards and housings

Lightweight, resilient components with optimised surface

Biocompatible surfaces for medical instruments

Mechanically highly stressed components with maximum wear resistance

Lightweight but extremely robust components

Optimal corrosion and abrasion resistance for chassis and engine parts

High-voltage insulation and thermal shielding

In addition to functional properties, anodising also offers visual design options. Colour anodising allows aluminium parts to be dyed in various colours – from black and bronze to vibrant shades. The colouring takes place in the open pores of the oxide layer and is permanently retained.

Colour anodised components combine protection and design. They are used in many areas, including:

Weather-resistant, coloured aluminium profiles

Colour coding for components

High-quality, customised surfaces for interior and exterior furnishings

Metalux offers anodising of aluminium in various sizes and weights. Our systems are designed to meet a wide range of requirements in order to realise individual customer wishes.

| Procedure / Processing | Length in mm | Width in mm | Depth in mm |

|---|---|---|---|

|

Chromic acid and hard and sulphuric acidanodise |

4600

|

420

|

1300

|

|

Sulphuric acid and hard anodising, various colours |

2600

|

300

|

1000

|

Anodising is a process that was specially developed for aluminium. Other metals such as titanium can also be anodised, but using different processes.

Black, bronze and various shades of grey are possible as standard. Strong colours such as blue, red or gold can also be achieved using special colouring techniques

Pure white cannot be achieved using the anodising process. However, aluminium can be brightened using special surface treatments or combined with a white top coat.

The maximum dimensions depend on the size of our system technology. We would be happy to advise you individually on your components.

The oxide layer grows directly out of the aluminium and is firmly bonded to the material. As a result, it offers long-lasting protection without flaking or wearing off.