Surface finishing in the

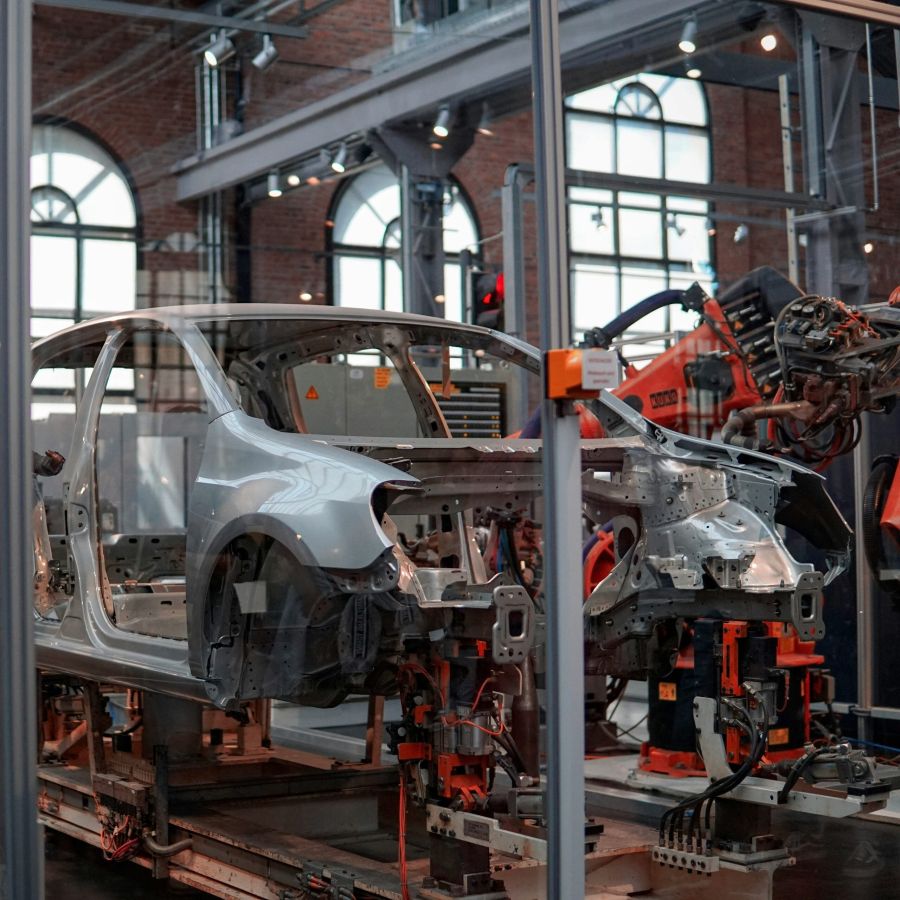

automotive industry

Technical and visual perfection for every vehicle generation

In the automotive industry, surfaces not only have to look good, they also have to function permanently. Corrosion protection, wear resistance, dimensional accuracy and visual requirements meet the highest quantities, strict standards and tight cycle times. Metalux offers certified and series-tested coating processes for applications in the interior, powertrain, chassis or housing construction.

The requirements for coated components in vehicle construction are as diverse as the vehicle itself. Components must function permanently under mechanical stress, temperature fluctuations, moisture and chemical influences. At the same time, design, feel and compliance with standards play a key role – especially in series production.

Metalux offers a wide range of surface finishes for this purpose, tailored to the specific areas of application in automotive technology.

Our processes are designed for reproducibility, series capability and process reliability. Documented, quality-assured and continuously monitored by our in-house laboratory.

As an experienced partner, we support our customers from component development through to series production. Economical, flexible and with a deep understanding of the requirements of the automotive industry.

Metalux stands for surfaces that think for themselves. Functional, resilient and ready for series production.

Typical are: