Chemical

nickel plating

Wear & corrosion protection for the highest demands

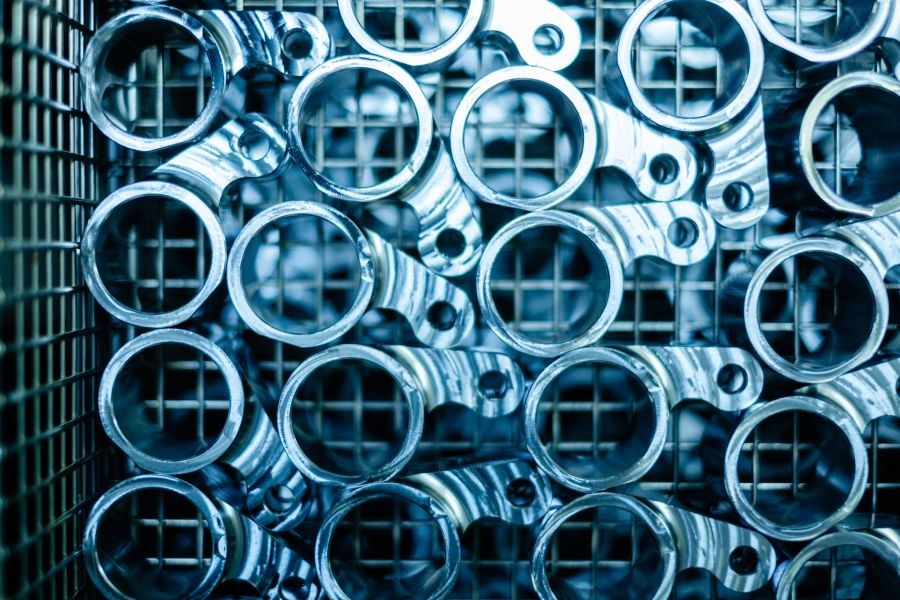

Chemical nickel plating is a high-precision process for surface finishing of metallic materials. The component is immersed in a nickel-containing process solution, which forms a uniform nickel-phosphorus layer without an external power source.

This layer offers excellent dimensional accuracy and protects against wear, corrosion and chemical influences, even in complex geometries with holes or cavities.

The hardness of the layer can be further optimised through targeted post-treatment to ensure maximum durability.

Chemical nickel plating offers decisive advantages compared to galvanic processes:

Ideal for complicated geometries & cavities

No layer build-up on edges & corners

Even under extreme conditions

Friction reduction for mechanical components

Versatile use

Specific customisation of the surface structure is possible by pretreating the base material.

Matt look

Metallic shine

Metallic bright with a slight yellow tint

The hardness can also be increased by tempering (heat treatment) to further improve abrasion resistance.

The wear resistance depends largely on the phosphorus content of the coating. The coating thickness also influences the mechanical load-bearing capacity:

Protection against mild corrosion

Medium wear & corrosion resistance

High stress, ideal for machine components

Extremely high load capacity for special applications

A chemically nickel-plated layer combines many functional advantages:

This property means that no complex post-processing is required, which makes the process particularly economical.

Electroless nickel plating ensures very even layer distribution, even in hard-to-reach areas such as:

The correct choice of coating thickness and phosphorus content is crucial to achieve optimum results.

Chemical nickel offers excellent corrosion resistance, in particular due to:

Metalux offers electroless nickel plating in various sizes and weights. Our systems are designed to meet a wide range of requirements in order to realise individual customer wishes.

| Procedure / Processing | Length in mm | Width in mm | Depth in mm |

|---|---|---|---|

|

Chemical nickel plating of steel |

1010

|

320

|

725

|

|

Chemical nickel plating of brass and stainless steel |

1010

|

320

|

725

|

|

Chemical nickel plating of aluminium |

1010

|

320

|

725

|

We will advise you individually on the optimum pre-treatment for your component!

In principle, many metals can be electroless nickel-plated. The following are suitable:

Without special pre-treatment

Requires activation & special pre-treatment

The coating is absolutely even, even on complex components – no edge effect!

Yes, tempering can further increase the hardness to improve wear resistance.

Thanks to its high phosphorus content and non-porous layer formation, the process offers excellent protection against corrosion.

Yes, the coating has good electrical conductivity and is suitable for electronics applications.